In the bustling world of modern manufacturing, welding machines are at the heart of almost every product you touch, see, or use. This indispensable, fiery craft is shaping the future of industries at a pace you won't believe.

The surge in technology advances and sustainability goals has made the role of welding machines more critical than ever. Why are manufacturers prioritizing this now? The answers are more surprising than you might think.

Here’s a kicker: welding isn’t just about putting two metals together. It’s the backbone of structural innovation, used in building everything from bridges to electric cars. Did you know it’s also used in challenging environments like underwater and outer space? But that’s not even the wildest part…

Consider this contrarian viewpoint: certain industries are achieving feats without human welders at all. Automation is taking the helm with robotic assistance, sparking debates over the future of skilled labor. You won’t believe what engineers are predicting next…

What happens next shocked even the experts—imagine a world where welding becomes a symbol of futuristic prowess as much as it is of craftsmanship. Are you ready to uncover how welding is truly transforming in front of our eyes?

At first glance, welding might seem like a straightforward process. However, its versatility is astonishing. From jewelry to skyscrapers, welding is integral to creating objects of every scale. Perhaps the most surprising revelation? Even delicate surgery tools utilize micro welding techniques for precision that technology alone can't achieve. But there’s one more twist…

Household items, from your refrigerator to your bicycle frame, owe their existence to welding. For instance, friction stir welding, a revolutionary technique, is commonly used in creating airtight components for planes. Next time you fly, remember that innovation in welding ensures your safety at 35,000 feet. And just wait until you hear what the future holds…

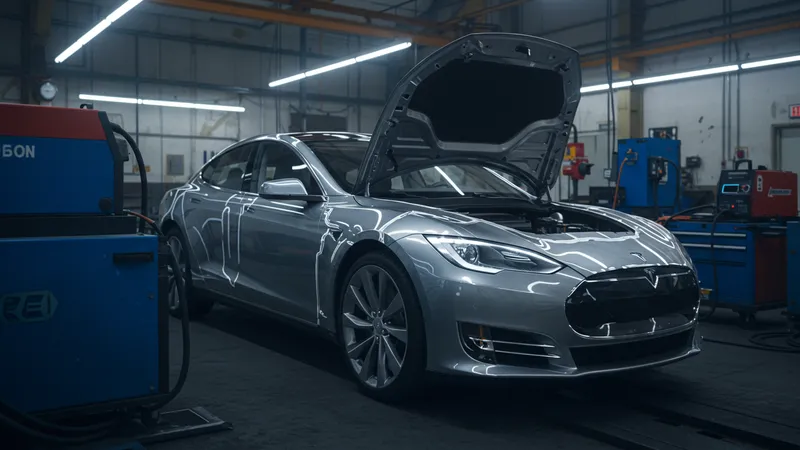

Insider tip: The auto industry employs laser welding to achieve unparalleled strength and precision. Dubbed the "invisible weld," this method is not only fast but also virtually flawless, reducing the risk of product recalls. Yet, manufacturers are keeping another innovation up their sleeves that might surpass this technique very soon…

Automated welding is redefining labor dynamics. Once heavily reliant on skilled human operators, industrial robots now carry out repetitive welding tasks with striking accuracy. They are not replacing humans but enhancing productivity, a partnership that could change manufacturing forever. What you read next might change how you see this forever.

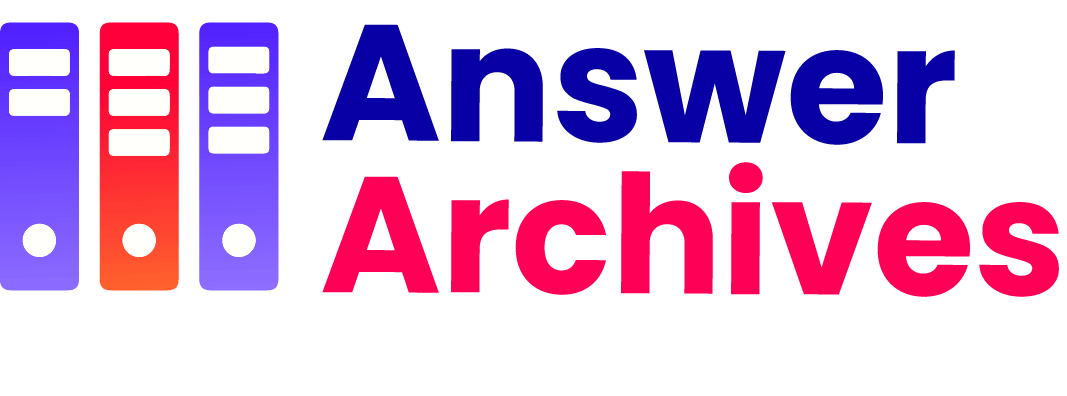

The automotive industry is one area where welding machines have had a profound impact. Look under the hood—literally—and you’ll find welding's handiwork in every nook and cranny of your vehicle. But what's truly compelling is how welding innovations are paving the road for electric cars. More on that breakthrough soon…

You’ve likely heard of the Tesla Model S, hailed for its streamlined design. It wouldn’t exist without aluminum welding, an art that prevents the usual pitfalls like cracking and warping. As electric vehicle (EV) demand grows, so does the need for specialized welding techniques that ensure lighter, more efficient builds. But there’s another frontier to explore…

The pioneering use of hybrid laser welding in vehicle manufacturing is creating robust joints with unparalleled durability. This is particularly crucial given the modern emphasis on eco-friendly materials. These welding methods are also seeing applications in developing hydrogen-powered vehicles, marking a significant shift in the automotive landscape. What might come next?

Beyond assembly, welding also plays a critical role in automotive repairs. The emergence of portable welding devices allows mechanics to perform complex repairs on-site, minimizing downtime and maximizing convenience. Imagine a time when car repairs become as quick as a phone call. The transformation is just starting, and you won’t want to miss what’s next…

Aerospace and welding are not words you often hear together, yet this duo is revolutionizing space exploration. Recent missions have relied heavily on innovative welding technologies to construct and maintain spacecraft. A single error could spell disaster, so welding precision is more crucial than anywhere else. But that’s not even the half of it…

Consider the advances in friction stir welding, a method that’s seen its heyday in the aerospace industry. It has enabled the production of rocket boosters and fuel tanks, reducing costs and enhancing safety measures. This technique continues to push the boundaries of what’s possible beyond our atmosphere. Yet, there’s so much more…

Did you know that every metal component aboard the Mars rover was meticulously crafted using specialized welding processes? These weren't just common practices; they involved cutting-edge technology to withstand extreme conditions. NASA and other space agencies are continuously experimenting with new welding techniques to further enhance exploratory missions. What comes next may surprise you…

Let's not forget aircraft manufacturing. The precision required in assembling aircraft fuselages is only made possible by advancements in welding technology. The emergence of some jaw-dropping techniques both challenge and surpass current engineering standards. These methods promise to reshape not just airplanes but the entire engineering sector. Here’s where things get wild…

Most think of welding as a spark-filled, metal-fusing process found in factories. But healthcare? It might shock you to learn that welding is quietly transforming medical tools and devices. From surgical instruments to complex machinery, welding provides the robustness and precision expected in a high-stakes field like medicine. The real surprise lies below…

Micro welding techniques have taken precedence in crafting ultra-tiny medical components, with laser welding leading the charge. Its pinpoint accuracy results in flawless devices that are not only reliable but life-saving. And guess what? These innovations are also reducing costs in medical equipment manufacturing, which is changing the dynamics of healthcare accessibility. But wait, there’s more…

The development of wearable medical technology, like heart monitors and insulin pumps, benefits significantly from advancements in welding. Secure, seamless joints ensure these devices are both effectively functional and safe for patient use over long periods. Enter the latest invention waiting in the wings…

In prosthetics manufacturing, welding is unlocking new realms, creating more durable and lightweight limbs. The possibilities are wide-ranging—custom-fit prosthetics integrated seamlessly with micro-sensors. This future tech means that the line between human and machine becomes increasingly blurred, challenging ethical boundaries and pushing scientific limits. And you won’t believe what’s being trialed right now…

Sustainability is the buzzword of our times, and welding practices are deeply rooted in its progress. The relentless push for green technology has put welding at the forefront of initiatives to curtail carbon footprints. What stands out is how ingenious welding techniques are spearheading the movement. Let’s dive deeper…

From solar panels to wind turbines, the role of welding in creating energy-efficient technologies is significant. Stronger, more sustainable materials have emerged through advanced welding processes, making renewable energy more achievable than ever before. But here lies a lesser-known fact…

One innovative method is ultrasonic welding, which eliminates the need for additional fasteners or adhesives. This technology is surfacing in electric vehicle battery manufacturing, reducing weight and improving efficiency. The subsequent benefits underscore a movement toward a cleaner planet. Yet, surprises await as industries delve deeper…

By welding biomaterials, we’re seeing a shift towards a circular economy where waste transforms into usable products. Cutting-edge welding is enabling these transformations, harmonizing industrial growth with environmental preservation. But there are new revelations on the horizon that could redefine our pursuit of sustainability…

Welding and defense seem like an explosive combination, don’t they? As it turns out, cutting-edge welding technologies are crucial in developing modern military equipment. These innovations not only enhance defense capabilities but reshape strategies. What might seem unconventional is actually quite the opposite…

The development of advanced armored vehicles owes much to welding prowess. Explosive reactive armor, for example, relies on precision welding to secure its high-tensile components. This enhances the durability of vehicles while improving mobility—a game-changer in military engineering. Brace yourself for the next revelation…

Beyond vehicles, welding plays a critical role in the production of precision weapons, from high-performance rifles to guided missiles. Welded components ensure performance integrity, a necessity in high-pressure environments. Yet, there are continuous advancements in stealth technology that keep experts guessing about future deployments. Here’s what’s emerging…

The exciting potential of additive manufacturing in military applications is hard to ignore. Using laser-based welding technologies, custom parts are created with unparalleled accuracy. This reduces lead times significantly and allows for rapid deployment of enhanced systems. The secrets of future warfare have welding at their core, expanding possibilities and uncertainties alike…

With an industry value projected in the billions, welding is a major player in the global economy. Its influence across multiple sectors makes it a linchpin that maintains economic stability. The underlying truths of its expansive reach might just redefine your understanding of manufacturing…

The demand for skilled welders has soared, resulting in strong job growth prospects. Industries from automotive to aeronautics are clamoring for expertly skilled artisans to meet their manufacturing needs. Surprisingly, this has ignited a new wave of educational and vocational training programs worldwide, but there’s more to the story…

New welding technologies are not only refining industry practices but are also breathing life into new sectors. For instance, advancements in underwater welding have broadened explorative capabilities in oil drilling and marine construction. These expansions have uncharted implications for the economy. Yet, the wider implications remain under wraps…

Welding fosters a ripple effect, enhancing supply chain dynamics and market growth. The creation and export of machinery and specialized welding equipment are vital for emerging economies. As nations invest in infrastructure, it showcases the potential for sizable economic benefits globally. But there’s an untold aspect that offers a fascinating twist…

The welding industry is experiencing a renaissance of sorts, as a new generation of skilled workers steps up to meet modern demands. As technology evolves, so does the artistry required in welding, bridging an ancient craft with futuristic possibilities. Imagine what's stimulating this renewed interest…

In response to the skills gap, companies are heavily investing in retraining programs, emphasizing sophisticated welding technologies. This drive for skill enhancement opens numerous career avenues for prospective welders. At the heart of this transformation? Gamified training methods engaging young minds as never before…

Technology is also at the helm of this renaissance through augmented reality (AR) training, providing an immersive way to learn complex welding techniques. This modern approach serves not only to capture interest but to improve safety by simulating risky tasks virtually. And what they’re discovering next is just as revolutionary…

The merger of tradition with technology has led to a revival in welding craftsmanship. Custom metalwork and artistic welding projects are burgeoning, providing not just functional value but aesthetic wonder. This amalgamation celebrates creativity alongside precision, pointing to a thrilling future for the craft. What follows next will redefine this fusion…

Welding and technology may not often appear in the same sentence, but technological leaps in this field are spectacular. Sci-fi-like innovations are fast becoming realities in the welding industry. Buckle up, because this rollercoaster of inventions will surprise you at every turn…

Have you heard of hybrid laser-arc welding? This technology merges the benefits of laser and arc welding, producing impeccable joints, even at lower costs. Pioneering projects note significant time reductions and labor savings, potentially reshaping industry standards. But it’s just the tip of the iceberg…

3D printing, paired with advanced welding processes, is on the horizon. This marriage expands the creative latitude of manufacturers, enabling intricate designs that defy traditional manufacturing constraints. The potential to shift from mass production to bespoke creations is staggering. Yet there’s a twist that’s even more compelling…

Robotic welding systems have matured to execute complex tasks with human-like dexterity, boasting AI-driven precision. These machines predict errors and self-correct, minimizing wastage and elevating output quality. As they evolve, they offer a glimpse into a future where machines complement human craftsmanship. But what’s just around the corner might excite you the most…

Safety is paramount in manufacturing, and advancements in welding technology are setting new standards. You might expect protective gear improvements, but there’s far more to the story. Explore the frontier of safety that welding is innovating…

A leap in fume extraction technology is significant; it lessens exposure to harmful gases and particles during welding. This advancement is vital in safeguarding both welders and nearby workers, fostering healthier work environments. However, the evolution doesn’t stop there…

The introduction of real-time monitoring systems has equipped welders with tools to maintain optimal working conditions. These systems alert users to potential hazards, allowing for immediate corrective actions. Many may view this as a safety net that was unimaginable just a decade ago. Another surprising sector-driving force follows…

Automated shutdown sensors in welding machines have become standard, drastically reducing the risk of accidents resulting from equipment malfunction. Their implementation is an industry-wide commitment to raising safety benchmarks. Is this the ultimate solution, or is there more yet to come? Let’s delve even deeper…

Education forms the backbone of innovation, particularly in a complex field like welding. The intersection of academia and industry is not only broadening the skillset of new welders but also paving the way for future breakthroughs. There’s a symbiotic magic developing right before our eyes…

Collaborations between universities and manufacturing giants are fostering research initiatives that push welding technology boundaries. Encouragements like scholarships and internships create a pathway for aspiring engineers to revolutionize current practices. This curiosity-driven approach sows seeds for exponential growth. Prepare to be even more intrigued…

Institutions are vanguard adapters of the latest technologies, such as dynamic simulators and virtual workshops, to enrich educational programs. The synergy between traditional methodologies and cutting-edge techniques heralds a promising era for educational advancement in welding. But this renaissance has a deeper context that’s compelling…

Students are not only learning but are also exposed to real-world applications early on, shortening the transition time from classroom to industry. This integration generates a workforce ready to tackle the challenges of modern manufacturing with innovative solutions. But does the learning stop here? Let us unveil what else brews on the horizon…

Welding may be a niche skill, but its implications are globally impactful. International collaborations and technological advancements are essential in galvanizing growth across continents. It’s a story of global convergence that’s only beginning to unfold…

Developing countries benefit immensely from welding, as they adapt tried-and-true techniques to elevate local infrastructures. Aid from wealthier nations, rich in knowledge and resources, sponsors growth initiatives and upskills domestic workforces. But there’s an aspect even more compelling…

These collaborative efforts are mutual, enabling developed countries to access raw materials and fresh markets. In turn, they overcome barriers and facilitate groundbreaking innovations. The relationship is intricate yet harmonious, fostering shared development goals. But that’s just one perspective…

Welding’s sustainability focus is contributing significantly to a globally green agenda. International standards are now reflective of ecological priorities, optimizing resource efficiency and cutting down industrial emissions. As industries align with environmental causes, a mutual respect and responsibility for our planet emerge. A finale to this intricate balance awaits…

The welding industry is positioned for remarkable advances, as ongoing research continues to push the limits of possibility. The blueprint for the future is drawn with unexpected elements poised to redefine welding. The groundwork is set, but you’ll be astonished by what’s predicted…

As artificial intelligence and machine learning gain traction, welding machines will develop brains of their own, drastically improving efficiency. A world where machines self-diagnose and rectify errors autonomously is no longer a dream—it’s around the corner. Yet, there's a vision that’s even more ambitious…

Envision materials that couldn’t traditionally be welded now feasible, thanks to advancements in material science. Breakthroughs in graphene welding bring unparalleled strength and electrical conductivity, opening new frontiers in engineering. As these developments unfold, we stand on the brink of a new industrial epoch. But what lies truly ahead is a revolution…

It’s more than technology; it’s a metamorphosis of talent, capacity, and necessity. The emerging era emphasizes sustainability, resilience, and interconnected systems. The welding industry you knew is a catalyst for extraordinary ingenuity, and this is just the start. Will you be a part of the journey ahead? Let’s find out…

In conclusion, as the welding industry enters this exciting phase, it's crucial to acknowledge its transformative power. From groundbreaking technologies to skillset evolution, welding is the unsung hero driving global manufacturing forward. The lesson is clear: innovation knows no bounds. Don't just brace for impact; contribute to it.

If this deep dive into the world of welding has captivated your imagination, share it with friends or bookmark it for future updates on this intriguing narrative. Whether you're a tradesperson, engineer, or curious reader, the story of welding is just as much yours as it is mine. Let's spread the word.